Application of Plasma Cleaning Machine in IC Chip Packaging

Plasma cleaning machine is an advanced cleaning equipment that can play an important role in the packaging process of IC chip manufacturing by using plasma technology to clean the surface of objects. This article will provide a detailed introduction to its application in IC chip packaging.

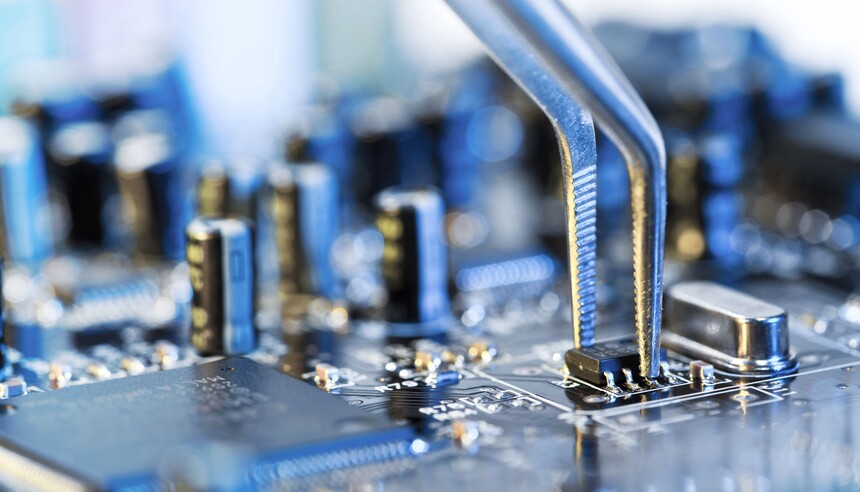

IC chip packaging refers to the process of sealing chips and circuit components inside a certain material to improve the stability and reliability of the chip, and cleaning work is essential in its manufacturing process. Plasma cleaning machines can easily clean dust, oil, and other pollutants in the packaging process of IC chips by generating high-energy electron beams and other high-energy particles.

b8b5ba0a85684e8cbaa05f0c6bd58c45.jpeg

Specifically, the application of plasma cleaning machines in IC chip packaging mainly includes the following aspects.

1. Remove the film. During the packaging process of IC chips, thin films may sometimes be generated, which may affect the quality and effectiveness of the chip. Plasma cleaning machines can remove these thin films from the surface of chips by generating high-energy electron beams.

2. Decontamination. During the packaging process of IC chips, some dust, stains, and oil stains may adhere to the chip surface, which can seriously affect the performance and quality of the chip. Plasma cleaning machines can generate high-energy electron beams and other high-energy particles to remove these pollutants from the surface of the chip, thereby improving the quality and reliability of the chip.

3. Increase adhesion. In the packaging process of passive devices, it is necessary to connect them to the metal surface. Plasma cleaning machines can generate a plasma ion source to spray suitable packaging coatings onto the surface of chips, thereby increasing their adhesion and reliability.

4. Remove static electricity. In the process of manufacturing IC chips, static electricity is also a very troublesome problem. Static electricity not only affects production efficiency, but also leads to inaccurate chip measurement results. Plasma cleaning machines can remove static electricity from the surface of chips by generating high-energy electron beams and ion sources, making their packaging more reliable and stable.

Overall, plasma cleaning machines are widely used in the packaging process of IC chips. It plays a crucial role in IC chip manufacturing by generating high-energy electron beams and other high-energy particles, which can quickly clean pollutants and other stains on the surface of IC chips, improve the quality and performance of the chips.

Recommend

-

-

QQ Zone

-

Sina Weibo

-

Renren.com

-

Douban